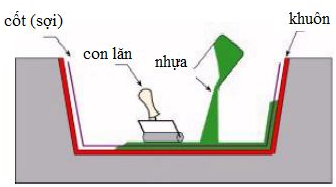

1. Roller technology

The roller technique is performed by soaking the fiberglass with a liquid resin (which may have been mixed or not with a curing agent). Products made from this process are products that are too large to be produced by other methods. This technique is used to manufacture small quantity products and to invest in tower production. For example: boats, chemical tanks, truck barrels...

2. Spray gun technology

The spray-gun technique is used as an alternative to the technique of fingerprinting, although they have several different characteristics. This technique is often used for molds that are too large to prepare fiber reinforcement because they are too heavy to handle. With the spray gun technique, the product is completed faster, the hand-over technique and can be used with the coating method and can be automated. Spray gun technology can be used to repair or reinforce metal containers inside, or outside, swimming pools and corrosion resistant structures. The spray gun can produce machine protection panels, bathtubs, truck barrels...

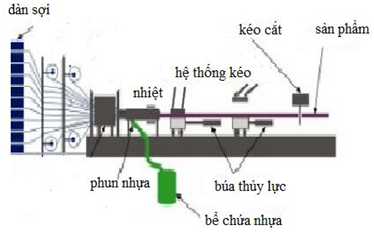

3. Pulltrusion technology

This is a technique used to produce conposite profile products by spinning the yarn through the plastic wetting part, shaping and curing. Raw materials used are roving fiber glass combined with thermosetting resin in liquid form such as polyester resin or epoxy resin. Today pultrsion technique is widely used in Japan, Switzerland, UK, Germany... The products of this method are usually in the form of tube or bar, used in electrical engineering and anti-corrosion. In addition, in the world with high-tech products, more advanced and complex machining methods are often used.

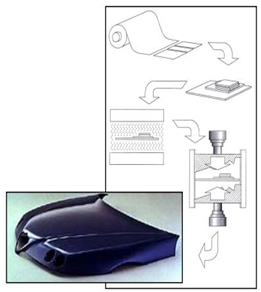

4. Compression molding technology

This technology uses the machine under pressure and has heating, the mold consists of 2 halves male and female. Under the pressure of force and compressive force and together with mold heating, curing reaction takes place causing the product to cure completely. This technology is used when it is manufactured in large quantity, using high compressive pressure, suitable for the manufacture of large parts by module and for smooth products on both sides, with precise shape in the mold. In Vietnam, this technology does not seem to be applied due to high equipment investment.

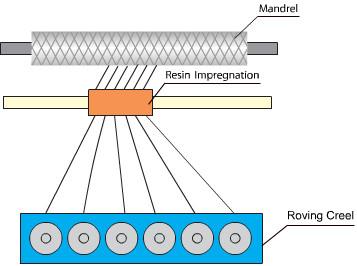

5. Yarn winding technology

Manufacture of cylindrical and spherical pressure tanks. Making products in the form of tubes, oxygen, gas and other gases. Make jet engine hulls, helicopter wings, spacecraft parts. Very large tanks, placed underground, (to store gasoline, oil, salt, acid, alkali, water. corrosion, reducing pipe damage even at high pressures.

BÀI VIẾT LIÊN QUAN